The global masterbatch market is witnessing a considerable growth over the past few years with the value of USD 9,763.17 million in 2020 (according to Grand View Research). This leads to an increasing demand for white masterbatch across various industries.

White masterbatch is a combination of titanium dioxide (TiO2), virgin resin and specific additives. In which, titanium dioxide (formular as TiO2) is the most important component that determines the degree of end-products’ brightness and transparency.

Generally, there are two types of TiO2 which are commonly used in the plastic industry: rutile and anatase. They both share great whiteness and brightness, but have different levels of dispersion and light resistance. Rutile disperses more evenly on the end-products’ surface as well as remaining in good condition under sunlight for a longer period than its counterpart. Hence, it is specifically preferred in outdoor applications, while anatase is more well-known for its indoor applications.

1. How does white masterbatch surpass other coloring methods?

There are several ways to color plastic including pigments, cube blends, pre colored resin (compound), and color masterbatch. Each of them has both advantages and disadvantages. However, color masterbatch may be the most common coloring method when manufacturers put the following factors into consideration:

- The level of dispersion: Color masterbatch offers better dispersion than that of pigments as it is in granular form.

- Mechanical properties: Color masterbatch often comes with several additional properties such as UV resistance, abrasion resistance, processing aid,…, thus improving end-products’ competitiveness.

- Storage and delivery: Unlike pigments, which usually cause airborne leading to the impurity and opacity of end-products’ surface, color masterbatch, thanks to its granular form, is more convenient to store and deliver.

- Reasonable price: Compared to pre colored resin (compounds), color masterbatch offers far more reasonable prices.

2. Common uses of white masterbatch

Thanks to its outstanding advantages, white masterbatch is widely used in various industries.

Packaging films

The demand for white masterbatch is increasing swiftly driven by the growth of the packaging industry. The global packaging industry is witnessing a significant growth driven by the consolidated development of subsegments such as food, industrial, retail, consumer, and medical packaging. According to a report from Grand View Research, the global plastic packaging market was valued at USD 348.08 billion in 2020 and is projected to grow at a CAGR of 4.2% over the forecast period.

Some common applications include shopping bags, garbage bags, roll bags, phar… By using white masterbatch, film layers are offered great dispersion, high level of brightness and UV resistance, thus increasing the content protective effectiveness. Also, it provides the films with a better look and longer service life, thus enhancing manufacturers’ competitiveness.

Raffia

PE and PP raffia is used in a wide range of applications, such as PP bags, laminated PP bags, and FIBCs (flexible intermediate bulk containers).

Very often, FIBCs are made of thick woven polypropylene fabric (usually 70-250 GSM), either coated or uncoated. As they are commonly used in containing dry, flowable products like sand, fertilizer, and granules, FIBCs require a high level of strength, flexibility and UV resistance.

Also, the sensitivity of raffia production makes the selection of white masterbatch critically important. They must be tailor-made to reduce water carry-over (WCO), to maintain high retention, and to better disperse on end-products. Also, white masterbatch needs to have a great UV resistance to prevent polymer degradation and yellowish effect.

Injection moulded items

Not only is white masterbatch applied in blown films, it is also added to caps and enclosures manufacturing process. Caps and enclosures are complex products, which are considered as “qualified” only if they are openable, resealable and securely contain the contents of the bottle, tub or tube. Hence, white masterbatch must be mindfully used to prevent unexpected shrinkage and warpage, and provide outstanding stress crack resistance for end-products.

Besides, white masterbatch is also incorporated into several applications such as table, chair, can, bottle, tray, box,… to enhance end-products’ whiteness and brightness.

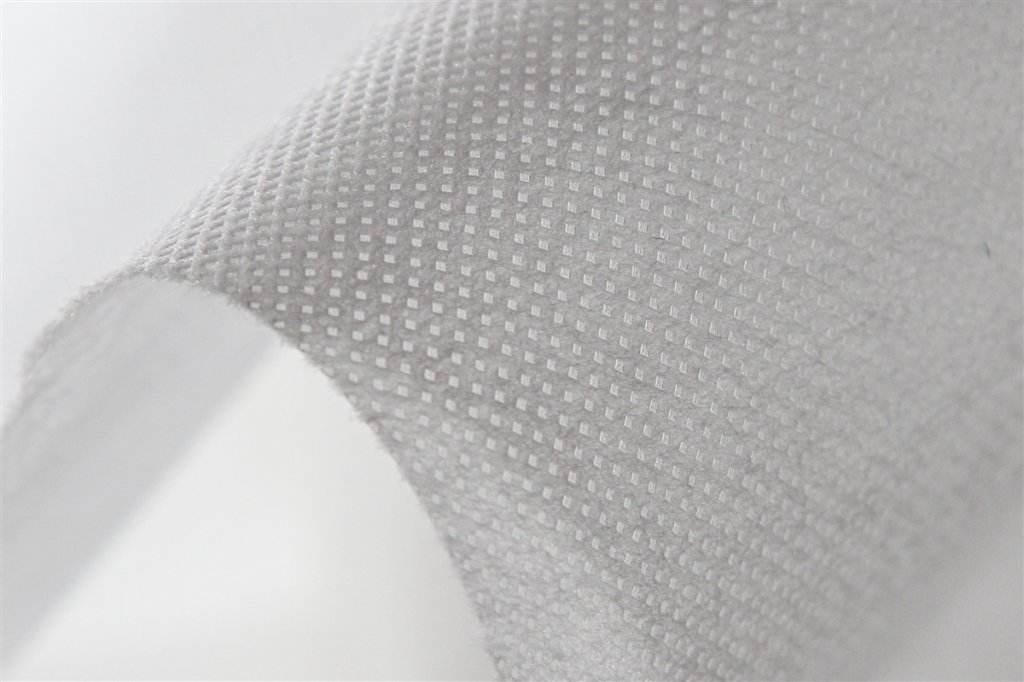

Non woven

PP & PET non-woven materials are widely applied in consumer products, hygiene, filtration and medicine, and non-disposables used in construction, electrical and electronics, carpets, rug and furnishings. As production of non-woven materials involves a highly-sensitive process, it is critical to select the correct white masterbatch that has high heat resistance properties and good dispersion.

Agricultural films

White masterbatch is widely used in various applications such as mulch film, silage film,… It increases photosynthesis in the lower leaves of the crop, which are usually shadowed by upper leaves, by reflecting sunlight towards them. As white color reflects more visible light than UV light, it is suitable for use with orchards and leafy crops, or when soil temperatures need to be cooled down.

Also, white masterbatch is customized based on particular requirements from manufacturers to offer additional benefits such as UV resistance, great dispersion and processing stabilization. Therefore, the incorporation of white masterbatch in end-products enhances the competitiveness of end-products.

Extrusion

This masterbatch is also used in manufacturing film sheets. It offers great dispersion and enhances mechanical properties for end-products such as heat resistance, weather resistance, processing ability,…

3. PolyFill white masterbatch

PolyFill is one of the leading filler masterbatch manufacturers in Vietnam providing customers with a wide variety of plastic fillers on various resins, which include plastic filler white.

In PolyFill, white masterbatch is manufactured by mixing high-quality titanium dioxide (TiO2), plastic resins and other additives. The most important is tailor made products to exactly fit with customer’s requirements. Before making an order, customers are requested to send the sample of the end-products as well as desirable properties of input materials, so that PolyFill can be able to create the most suitable material. That’s why PolyFill takes pride in offering customers the most excellent properties and quality.

The technical properties of our plastic filler white are as follows:

- Carrier resin: Polyethylene

- Appearance (Surface Color): White

- Additives: Dispersion agent, processing aid

- Pellet Size: 3×3 (±0.3) mm

- Packing: 25 kgs per PP bag

- Storage: Keep in dry condition

For further information, consultation and free sample, contact us HERE!