Plastic products are being increasingly used in daily life. Polystyrene (PS) – is one of the most commonly usedfor them today. From PS and the needs of plastic manufacturers in the new era, Polyfill has successfully researched and created HIPS filler masterbatch products.

What is HIPS filler masterbatch?

HIPS filler masterbatch is one of the products used to replace HIPS plastic while still ensuring the quality as the manufacturers require. The reason is that the component makes of this filler. Indeed, this filler masterbatch includes high impact polystyrene (HIPS), calcium carbonate powder and additives. Please check it below for more details!

HIPS

Before finding out more information about HIPS, we need to know about PS resin (Polystyrene) first. This is a thermoplastic resin, formed from styrene polymerization and it is recyclable. Indeed, the identification of this plastic is: hard, transparent, odorless and when it burns, the fire is not stable. Because PS is a colorless material, so it is very convenient for manufacturers to add colors with black masterbatch or white, red, blue masterbatch…Along with beautiful external forms, the manufacturers can use it by working with many methods such as injection molding. There are two representatives of PS are: HIPS and GPPS.

Due to this origin, HIPS – high impact polystyrene – has many characteristics of PS. In addition, HIPS is a low-cost, very versatile and good impact resistant plastic. That is the reason why people usually use HIPS for producing pre-production prototypes. It is easy for them to fabricate with high stability.

Related: PP filler masterbatch and 4 reasons to apply

Calcium carbonate powder

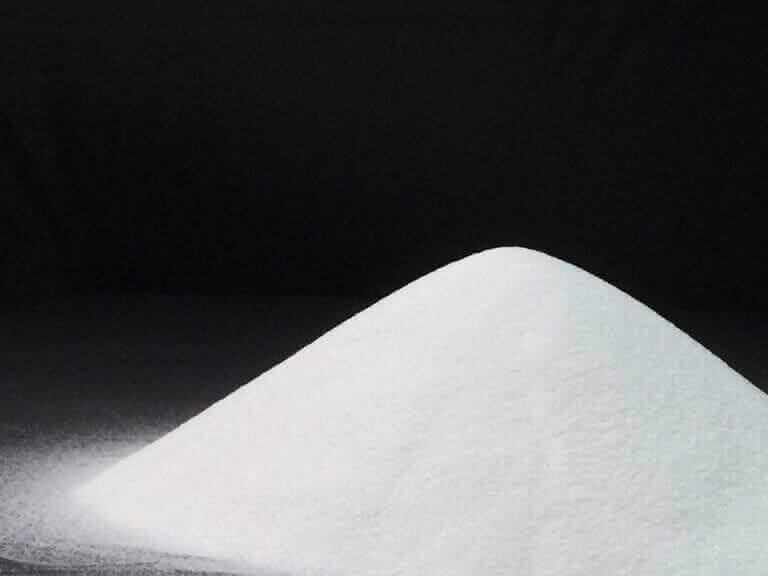

This powder is known as CaCO3 powder. From natural limestone, operators often produce this powder properly. Depending on the mining areas and customer requirements, they produce many types of CaCO3 powder. Calcium carbonate may vary in size, whiteness, moisture, apparent specific gravity, insoluble residue in HCL or chemical compositions. Because of its low price and many good effects, manufacturers utilize CaCO3 in many industries.

For example, people often use it in the paint industry as a main filler. The fineness and particle-size distribution of calcium carbonate affect the gloss of the coating process. In addition, CaCO3 powder has high brightness, low oil absorption, good dispersion, durability in the environment, low abrasion ability and stable pH. Morover, they also use CaCO3 powder in paper, rubber, masterbatches, Art marble… At Polyfill, we only use the high portion of ultrafine CaCO3 powder to make HIPS filler masterbatch. The main purpose of this step is to help the end product create a smooth and beautiful surface but still has high compatibility.

Additives

Additives are one of the indispensable ingredients in the plastic industry. It assists in the production process with molds as well as increasing the physical properties of products according to customer requirements.

Related: What is filler masterbatch and how it is applied in plastic industry?

Applications of HIPS filler masterbatch in plastic products

With a lot of advantages above, HIPS is a filler masterbatch which suitable for Indoor signage, CD case and fabrication. Although PS has a melting point from 210 to 240 Celsius degree, the heat resistance of HIPS filler masterbatch from Polyfill can reach up to 300 Celsius degree. That means plastic products from it still keep hardness in the high temperature. For this reason, You can find this kind of plastic in consumer products. For examples, appliance components, kid toys, televisions.

In fact, producers also use HIPS in automotive industry for auto parts, such as fuel tanks. Another case is in food service industry, while hot or cold drink glasses you get from bartenders maybe made from this filler masterbatch.

6 Comments

Hips fillers requirements

Monthly 50 MTONS

Hi! Thank you for messaging us. May we know your email address so our sales staffs can provide you with timely support?

Required Grey & Blue colour masterbatch for HIPS

Hi! Thank you for messaging us. May we know your email address so we can provide you with timely support?

Dear sirs,

We are producing small – thin wall-components for shaving razors (injected PS) can we use filler masterbatch to reduce the cost

Thank you in advance

Hi! Thank you for messaging us. We’ll need more information regarding your end-products and your current formular to deliver the answer to you. So could you leave your email address so we can put you through our sales staffs who can holdheartedly support you?