For any SME or OME who produces materials or articles which are supposed to contact to food, the FCMs supply chain is in need when they think about spreading their market share out of their circumscription in other nations.

The identification of materials and/or articles supplied requirement follows FCMs

Article 17 of the framework regulation states that business operators must have in place systems and procedures to allow identification of the business from which and to which materials or articles are supplied and that the materials and articles must be identifiable to allow their traceability by labeling or via relevant documentation.

The ‘Industrial guidelines on traceability of materials and articles for food contact’ (2006) define two levels of traceability, as follows.

- Level 1: within the operation of each stakeholder. This level covers the systems that each stakeholder has in place to link their products to the raw materials used to produce them.

- Level 2: between different stakeholders. This level is concerned with the transmission of information along the chain. It should be possible from any point downstream, and in particular from the retailing point, to go back up the chain to understand by whom the material or article has been manufactured. This also implies that, in the opposite direction, the material or article can be traced from any point up the chain down to the retailing point. Both levels must function to achieve full traceability.

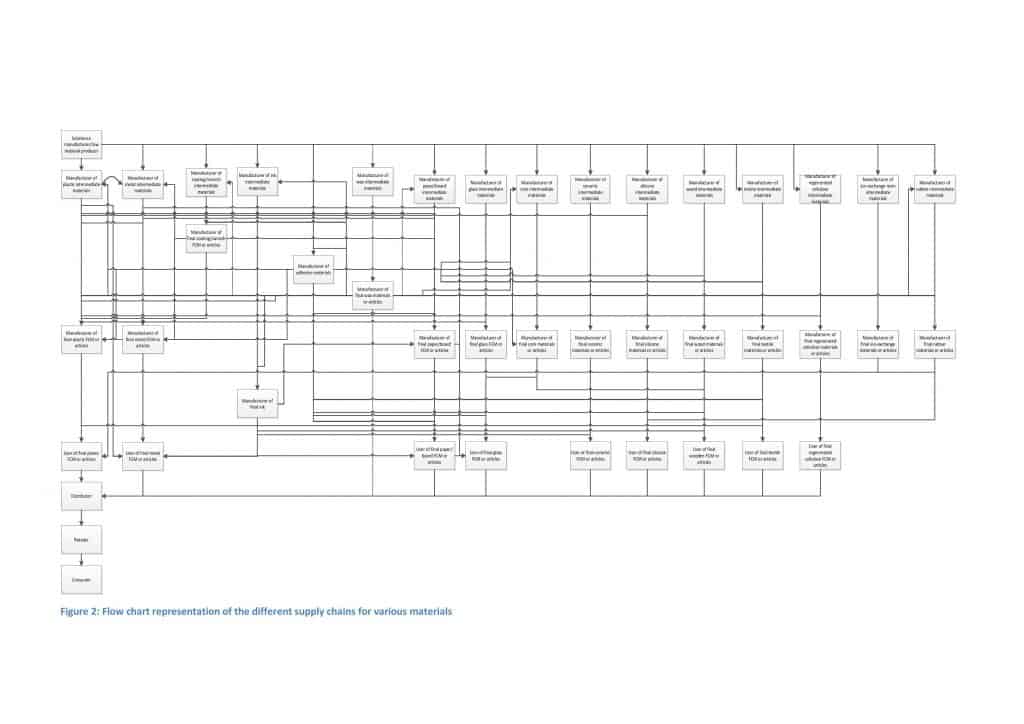

The industrial guidelines give a simplified structure of the organisation of the FCM supply chain, as is illustrated in the following figure.

Figure 1: Simplified structure of the organisation of the FCMs supply chain

The guideline states that ‘using the above diagram, it is possible to identify a point where the FCM or article is manufactured, i.e. the converters and producers. At this point, there is a separate identity, “upstream” and “downstream”. Converters transform materials, which have been produced by “upstream” suppliers, into finished articles or semi-finished goods. Producers manufacture articles directly from starting materials, using processes involving chemical, as well as physical change.’

FCMs influential on stakeholders or strategic supply partners

The scheme illustrated above assumes that the whole chain is within the EU. However, in some cases, part of the chain can be outside the EU; therefore another stakeholder should be included in the scheme, namely the importer. Imports may take place at different stages of the supply chain, such as:

- Import of starting materials by the converters and producers;

- Import of empty packaging by distributors or fillers;

- Import of finished articles such as kitchenware/tableware by distributors or retailers;

- Import of filled packaging by distributors or retailers.

In an ideal supply chain, e.g. a chain composed entirely of ISO 9000 certified companies, traceability will always be guaranteed, as every single step of the chain will have been documented. In practice, different identification rules may apply for upstream and downstream users. Upstream suppliers supplying a company operating under a certified quality system shall strictly guarantee the traceability of their products. It is essential that companies operating under a certified quality system control their suppliers and ensure that the supplied products are appropriately identified.

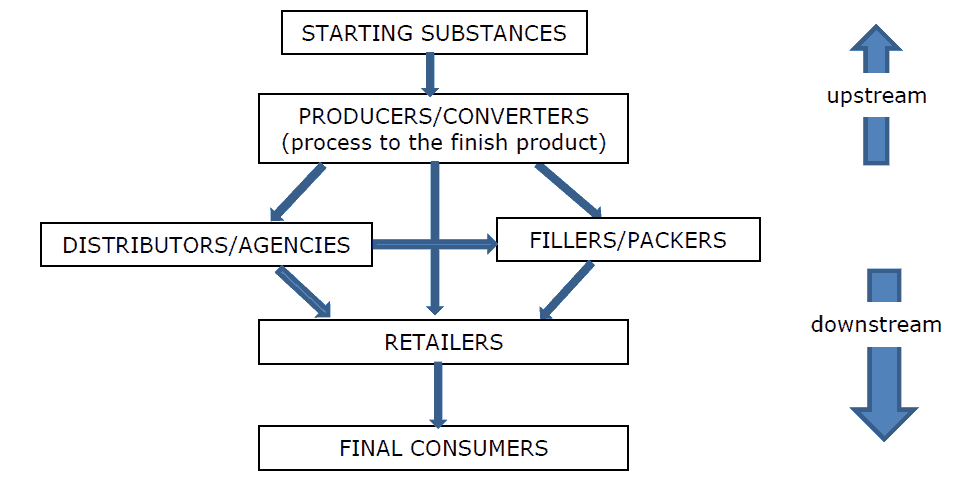

Figure 2 is an attempt to visualise the supply chain across the various materials. Since importers can act in the whole supply chain, they have been omitted from the figure.