Polymers grouping Based on Source

Regular Polymers: These polymers are found in plants and creatures. Cases are proteins, cellulose, starch, saps and elastic

Semi-engineered Polymers: Cellulose subsidiaries as cellulose acetic acid derivation acetic acid derivation (rayon) (rayon) and cellulose nitrate, nitrate, and so on are the standard cases of this sub classification

Manufactured Polymers: An assortment of engineered polymers as plastic (polythene), manufactured filaments (nylon 6,6) and engineered rubbers (Buna – S) are cases of man-made polymers

Grouping Based on Backbone of the polymers chain

Natural and Inorganic Polymers: A polymer whose spine chain is basically made of carbon particles is named as natural polymer The iotas connected to the side valencies of the spine carbon molecules are, in any case, notwithstanding, for the most part for the most part those of hydrogen, hydrogen, oxygen, oxygen, nitrogen, nitrogen, and so forth. The larger part of engineered polymers are natural On the other hand, for the most part chain spine contains no carbon particle is called inorganic polymers Glass and silicone elastic are cases of it.

Order Based on Structure of Polymers

Direct Polymers: These polymers comprise of long and straight chains. The illustrations are high thickness polythene, PVC, and so on. Direct polymers are usually moderately delicate, regularly rubbery substances, and frequently prone to mellow (or soften) on warming and to break down in certain dissolvable .

Fanned Polymers: These polymers contain direct chains having a few branches, e.g., low thickness polythene .

Cross-connected Polymers: These are typically shaped from bi-practical and tri-useful monomers and contain solid covalent bonds between different straight polymer chains, e.g. vulcanized elastic, urea-formaldehyde tars, and so forth. Cross connected polymers are hard and don’t liquefy, mollify or break down as a rule.

Arrangement Based on Composition of Polymers

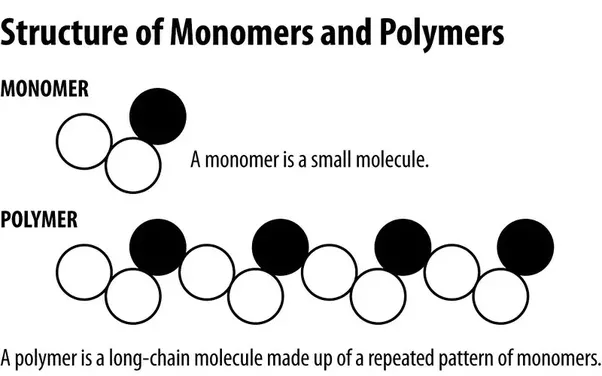

Homopolymer: A polymer coming about because of the polymerization of a solitary monomer; a polymer comprising significantly of a solitary kind of rehashing unit .

Copolymer: When two distinct sorts of monomers are participated in a similar polymer chain, the polymer is known as a copolymer.

Polymers grouping Based on Mode of Polymerisation

Expansion Polymers

The expansion polymers are shaped by the rehashed expansion of monomer atoms having twofold or triple bonds, e.g., the development of polythene from ethene and polypropene from propene However, the expansion polymers framed by the polymerisation of a solitary monomeric animal varieties are known as homopolymer, e.g., polythene The polymers made by expansion polymerisation from two distinct monomers are named as copolymers, e.g., Buna-S, Buna-N, and so forth

Buildup Polymers

The buildup polymers are shaped by rehashed buildup response between two diverse bi-practical or tri-useful monomeric units In these polymerisation responses, the disposal of little atoms, for example, water, liquor, hydrogen chloride, and so on occur The illustrations cases are terylene (dacron), (dacron), nylon 6, 6, nylon 6, and so forth For e.g., nylon 6, 6 is framed by the buildup of hexamethylene diamine with adipic corrosive It is likewise conceivable, with three utilitarian gatherings (or two unique monomers no less than one of which is tri-useful), to have long linkage arrangements in two (or three) measurements and such polymers are recognized as cross connected polymers.

Polymers order Based on Molecular Forces

The mechanical properties of polymersare administered by intermolecular powers, e.g., van der Waals powers and hydrogen bonds, show in the polymer, these powers additionally tie the polymer chains Under this classification, the polymers are ordered into the accompanying gatherings based on greatness size of intermolecular powers exhibit display in them, they are: Elastomers, Fibers, Liquid saps, Plastics (which incorporates Thermoplastic and thermosetting plastic)

Elastomers

These are elastic – like solids with flexible properties In these elastomeric polymers, the polymer chains are arbitrary snaked structure, they are held together by the weakest intermolecular powers , so they are exceptionally indistinct polymers These frail restricting powers allow the polymer to be extended A couple of ‘crosslinks’ are presented in the middle of the chains, which assist the polymer with retracting to its unique position after the power is discharged as in vulcanized elastic The cases are buna-S, buna-N, neoprene, and so forth

Strands

In the event that drawn into long fiber like material whose length is no less than 100 times its measurement, polymers are said to have been changed over into ‘fiber’ Polymeric chains are straight chain polymers, they are held together by the solid intermolecular powers like hydrogen holding, these solid powers likewise prompt close pressing of chains and along these lines confer crystalline nature Fibers are the string shaping solids which have high elasticity and high modulus Examples are polyamides (nylon 6, 6), polyesters (terylene), and so on.

Fluid Resins

Polymers utilized as cements, preparing compound sealants, and so on in a fluid shape are portrayed fluid tars, illustrations are epoxy cements and polysulphide sealants.

Plastics

A polymer is formed into hard and intense utility articles by the utilization of warmth and weight; it is utilized as a ‘plastic’ The intermolecular power between polymeric chains are middle of the road amongst elastomers and strands, so they are incompletely crystalline.

Run of the mill cases are polystyrene, PVC and polymethyl methacrylate. They are two writes: Thermoplastic and Thermosetting plastic.

Thermoplastic Polymers

A few polymers diminish on warming and can be changed over into any shape that they can hold on cooling The way toward warming, reshaping and holding the same on cooling can be rehashed a few times, such polymers, that mollify on warming and solidify on cooling, are named ‘thermoplastics’ These are the straight or somewhat marginally spread stretched long chain particles atoms able to do more than once softening on warming and solidifying on cooling These polymers have intermolecular powers of fascination middle amongst elastomers and filaments Polyethylene, PVC, nylon and fixing wax are cases of thermoplastic polymers.

Thermosetting Polymers

A few polymers, then again, experience some synthetic change on warming and change over themselves into an infusible mass They resemble the yolk of egg, which on warming sets into a mass, and, once set, can’t be reshaped. Such polymers, that wind up infusible and insoluble mass on warming, warming, are called ‘thermosetting” ‘thermosetting” polymers. These polymers are cross connected or vigorously stretched atoms, which on warming experience broad cross connecting in molds and again wind up infusible These can’t be reused. Some normal illustrations are bakelite, urea-formaldelyde saps, and so on.