Polypropylene PP Filler Briefing

Polypropylene PP Filler is a promising plastic by demonstrating its awesome synthetic, physical and mechanical properties, comprehension and contrasting between PP writes and additionally thermoplastics to recognize their advantages and disadvantages, giving a far-reaching clarification with respect to Dow/UNIPOL PP innovation process, and including broad audits on the endless number of PP applications.

PP is the primary yield of propylene among different subsidiaries with 66% utilization rate. PP is the lightest kind of plastics with a thickness of 0.90 g/cm3. Homo-polymer PP (HPP) has a piece of the pie of 65-75%. Stretching, fortifying and filling PP are a few methods to create plastics with prevalent mechanical properties. Semi-crystalline isotactic polypropylene (iPP) demonstrated suitable optical qualities after reusing. BOPP and PP-OH films are perfect plastics for electrical applications. There are 26 working PP plants and 4 PP plants in development around the world. PP applications incorporate, however not restricted to, textures, films, containers, sheets and car items.

Polypropylene PP Filler and other kinds of plastics

Plastics are sorted into four primary gatherings: thermoplastics, elastomers, thermosets and polymer mixes. Macromolecular structures recognize the class of any plastic material and in addition its physical properties. Elastomers and thermosets have delicate and hard flexibility, individually; and their gums can’t be softened for reusing purposes. Nonetheless, thermoplastics are either formless or semi-crystalline. Shapeless gums are cluttered measurable situated macromolecules though semi-crystalline saps macromolecules are about arranged since they are installed with crystalline stages. Average shapeless pitches are polycarbonate (PC), polystyrene (PS) and polyvinylchloride (PVC) where run of the mill semi-crystalline saps incorporates polyamide (PA) and polypropylene (PP). Since PP is under the semi-crystalline class, our emphasis will be on this gathering.

Polypropylene PP Filler and its profile

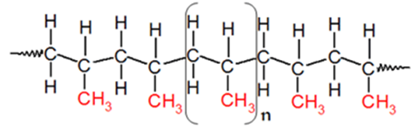

Polypropylene was found in 1954 and picked up a solid prevalence rapidly because of the way that PP has the most reduced thickness among product plastics. PP has an amazing synthetic obstruction and can be handled through numerous changing over techniques, for example, infusion trim and expulsion. Polypropylene is a polymer arranged chemically from propylene. It is significant preferred standpoint is identified with the high temperature opposition which makes PP especially appropriate for things, for example, plate, pipes, buckets, bottles, carboys and instrument shakes that must be sanitized (cleaned) oftentimes for use in a clinical domain. Polypropylene is a free-shading material with magnificent mechanical properties and it is superior to polyethylene for the past reasons. Polypropylene is a downstream petrochemical item that is gotten from the olefin monomer propylene. The polymer is created through a procedure of monomer association called expansion polymerization. In this procedure, warm, high-vitality radiation and an initiator or an impetus are added to consolidate monomers together. In this way, propylene atoms are polymerized into long polymer particles or chains. There are four distinct courses to upgrade the polymerization of any polymer: arrangement polymerization, suspension polymerization, mass polymerization and gas-stage polymerization. Be that as it may, polypropylene properties change as per process conditions, copolymer segments, sub-atomic weight and sub-atomic weight dissemination. Polypropylene is a vinyl polymer in which each carbon iota is connected to a methyl gathering and can be communicated as appeared in Figure 1.

Figure 1: Polypropylene structure

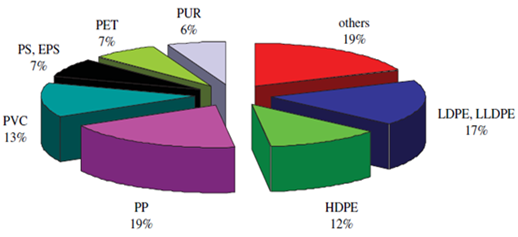

The yearly worldwide interest for plastics achieved 245 million tons and it is undertaking to develop significantly in light of the expansion openly request. Figure 2 demonstrates the aggregate plastics request by 2006. Around 90% of the aggregate request is represented five fundamental item plastics: polypropylene (PP), polyethylene (PE), polyvinyl chloride (PVC), polystyrene (PS) and polyethylene terephthalate (PET). In 1954, Giulio Natta found PP, yet business creation started in 1957. PP is the most broadly utilized thermoplastic since it is extremely shoddy and adaptable for trim. The second regular plastic compose is PE. There are distinctive evaluations of PE direct low thickness (LLDPE), low thickness (LDPE), medium thickness (MDPE) and high thickness (HDPE). The thickness of PE grades runs between 0.925-0.965 and clearly is higher than PP. Nonetheless, the uniqueness of PVC is related with chlorine content (57 wt. %) in its structure. Yearly overall PVC request is around 35 million tons. As indicated by past examinations, plastics are the most recyclable materials and there were 4.4 million tons of plastics reused in 2006.

Figure 2: World plastics demand by resin types 2006 (49.5 million tons)

Polypropylene synthetic opposition

Polypropylene synthetic opposition can be depicted as takes after: phenomenal protection from weaken and thought acids, alcohols and bases, great protection from aldehydes, esters, aliphatic hydrocarbons, ketones and constrained protection from sweet-smelling and halogenated hydrocarbons and oxidizing specialists. Polypropylene has a crystalline structure with an abnormal state of solidness and a high dissolving point contrasted with other business thermoplastics. The Hardness came about because of the methyl bunches in its atomic chain structure. Polypropylene is a lightweight polymer with a thickness of 0.90 g/cm3 that makes it reasonable in numerous modern applications. All things considered, polypropylene isn’t appropriate to be utilized at temperatures beneath 0°C. Analyses demonstrated that polypropylene has fantastic and attractive physical, mechanical, and warm properties when utilized as a part of room temperature applications. It is moderately solid and has a high liquefying point, low thickness and generally great protection from impacts. Run of the mill crystallinity of PP is between 40-60%. PP is a minimal effort thermoplastic polymer with fantastic properties like fire opposition, straightforwardness, high warmth bending temperature, dimensional security and recyclability making it perfect for an extensive variety of uses.

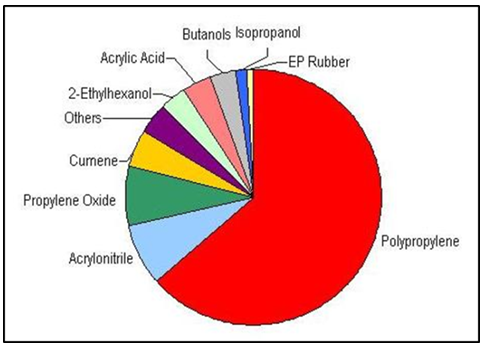

Propylene is a standout amongst the most essential modern petrochemical building squares used to deliver different compound subsidiaries. The overwhelming outlet for propylene is PP which represents almost 66% of worldwide propylene utilization as appeared in Figure 3. There are three noteworthy wellsprings of propylene: from steam breaking of naphtha, gas refining procedure and propane dehydrogenation innovation. Polypropylene is the most critical material among polyolefins because of three principal reasons. Initially, extraordinary properties of PP, for example, low thickness, high softening temperature and concoction dormancy with minimal effort making PP ideal for long-life applications. Second, polypropylene is an exceptionally flexible material implying that assorted variety in auxiliary plans and mechanical properties are achievable. Third, unique morphological structures of PP are conceivable by utilizing fillers or strengthening operators and mixing PP with different polymers which respect have predominant qualities. Extraordinary and fortified polypropylene grades incorporate elastomer-altered PP, elastomer adjusted filled PP, glass fiber-strengthened PP, filled PP, tasteful filled PP, fire resistant PP and thermoplastic elastomers.

Figure 3: Global propylene consumption (two-thirds for polypropylene)

An examination demonstrates that fanning procedure of direct Ziegler– Natta polypropylenes is conceivable by making chains in view of the atomic weight circulation. Bringing stretching into a direct polypropylene will bring about having an item with high atomic weight, high dissolve quality and better properties like high modulus and elasticity, inflexibility and great warmth obstruction. Stretching parameters β, the normal number of branch focuses per atom, and λ, the quantity of branch focuses per 103 carbons, are ascertained to distinguish the polymer structure and properties. A post-reactor is utilized for the spreading procedure. The fanning productivity is related with concoction structure and temperature of the response. The connection between spreading parameters and sub-atomic weight is critical to outline polymers with exceptional properties for various applications.

PP is extremely appropriate for strengthening and filling. Accordingly, another investigation centers around concentrate the impact of strands fortification on the mechanical properties of fiber-strengthened polypropylene composites (FRPCs). A composite material is a polymer framework that is inserted with fortification strands, for example, glass or carbon. FRPCs have better sturdiness, dampness opposition and high quality properties; making them perfect in applications identified with developments, sports hardware and autos. Engineered strands respect have better mechanical properties contrasted with common ones. Glass filaments are broadly utilized as a manufactured support with PP to create great mechanical properties composites. Be that as it may, mechanical qualities of composites are controlled by various fiber medicines and coupling specialists. Fiber distance across is another noteworthy factor in planning composites material. A specific estimation of fiber distance across thickness ought not be surpassed; if so strands will diminish composites quality. Electrically conductive PP and PE composites are savvy, monetarily demonstrated and with exceptional electrical and mechanical properties. It is compulsory to comprehend the conveyance, introduction, communication and viewpoint proportion of conductive fillers with the polymer framework to get the required conductivity. Better filler-grid connections are achievable at low thickness, low surface strain and high crystallinity. Uniting strategy starts the collaborations and the conveyance of the fillers with PP and PE grids.