The pipe extrusion process is a part of numerous assembling frameworks, including car segments among numerous different applications.

About the pipe extrusion process

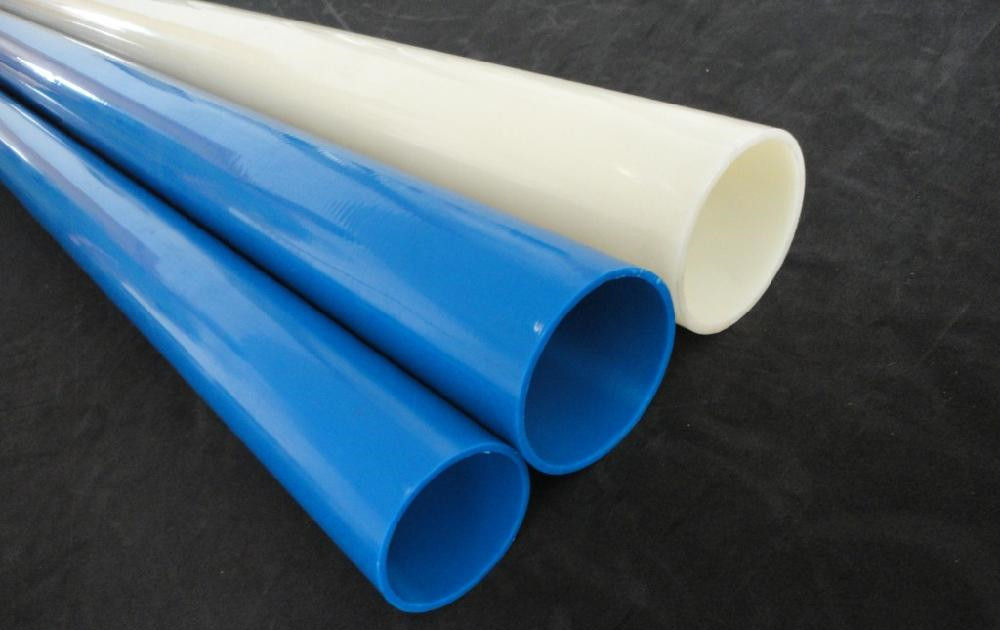

Extrusion is a procedure whereby a material is dissolved and framed into a constant shape that may then be cross-separated. Utilizing plastic materials, the pipe extrusion process can create tubing of different sizes that is utilized as a part of a wide assortment of uses and ventures, including different car segments.

Insights about pipe extrusion process

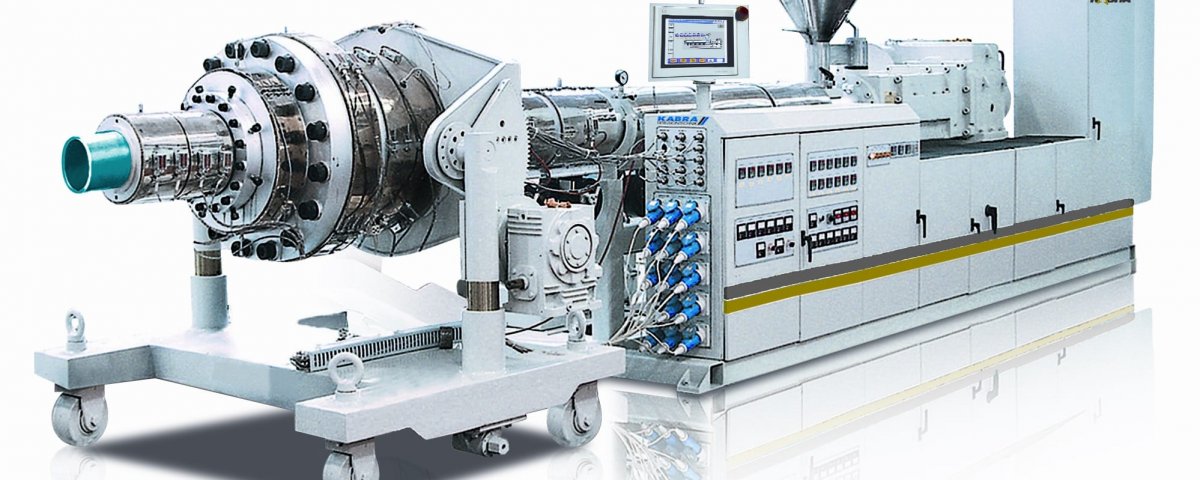

At its most essential, the pipe extrusion process includes encouraging the material into one end of a container where it is liquefied and after that constrained through a pass on which frames it into a pipe. The material slowly solidifies as it cools. The plastic may come as pellets or another crude frame. Tar may likewise be utilized. The assembling procedure is ordinarily set up as gravity sustained, with the container mounted over a barrel, where the liquefying happens. Warming is frequently performed in numerous phases that turn out to be continuously more sizzling. Continuous warming is best since it abstains from overheating and harming the plastic polymer.

Quality Control is significant to the pipe extrusion process

The kick the bucket is outlined so the liquid thermoplastic material streams equitably around it to frame a chamber of the coveted size and shape. An even stream is basic to keeping up the general honesty of the last item. Varieties in the stream can deliver frail zones. When it has been shaped, the plastic material starts to cool and solidify, a procedure regularly helped by an icy water shower. The subsequent channeling or tubing is then sliced to wanted lengths and wound in anticipation of utilization or transportation.

Different employments of the pipe extrusion process

Plastic extrusion is utilized to create an assortment of shapes notwithstanding funneling. The extrusion procedure may likewise be utilized with aluminum to create aluminum tubes utilized for such applications as water system funneling and electrical transmitters among others.

Steady advancement in assembling forms for pipe extrusion

At the Tecnomatic Group, we put stock in working inside a domain of steady advancement and change, while keeping up naturally well-disposed models. Our master workforce can configuration procedures and determinations to fit your needs with astounding outcomes.

2 Comments

Hello Sirs

Our company uses your filler masterbatch code EFPP 80

We produce pp pipes for sewage mixing PP copolimer with your filler

In fact the pipe stay still flexibel

Can you advise us for what to do to make more rigid the pipe

and what percentual you advice us in the mixture with pp

Dear Sir,

Thank you so much for replying us. Our sale staffs will respond your request through your email.

In case you have any other problems, please free to post your question at this link: https://polyfill.com.vn/contact/