In the ever-evolving landscape of plastic manufacturing, the choice of the right talc filler masterbatch exporter can significantly impact product quality, cost-efficiency, and overall competitiveness.

Our blog “Top 5 Famous Talc Filler Masterbatch Exporters” delves into the world of industry leaders dedicated to providing high-quality solutions. These renowned companies have earned their place in the global market through unwavering commitment to innovation and excellence.

From enhancing mechanical properties to improving thermal stability, the products offered by these exporters play a vital role in various industries. Join us on a journey to explore the top 5 exporters that are driving innovation and reshaping the future of plastics.

1. Overview of talc filler masterbatch

Talc filler masterbatch is a crucial component in the field of plastic manufacturing. In this section, we’ll delve into its definition and explore the advantages of using talc filler masterbatch in various industries.

1.1. Definition

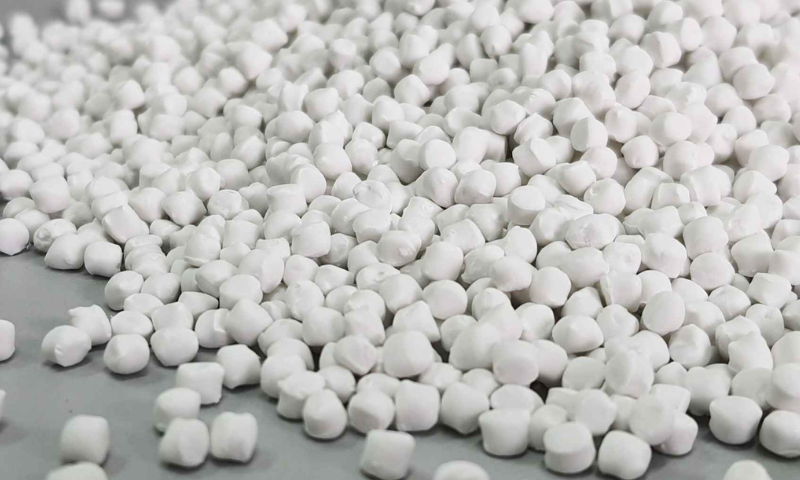

Talc filler masterbatch, often referred to as talc masterbatch or simply talc filler, is a specialized additive used in the plastics industry. It consists of a high percentage of talc, a naturally occurring mineral known for its unique properties, finely ground and dispersed into a carrier polymer matrix. This masterbatch is designed to enhance the properties of plastic materials during the manufacturing process.

Talc, chemically known as magnesium silicate, is valued for its unique combination of properties, including its lamellar structure, which imparts excellent reinforcing and anti-blocking characteristics to the masterbatch. This versatile material is highly regarded for its ability to improve the performance and cost-effectiveness of a wide range of plastic products.

1.2. Advantages of using talc filler masterbatch

The use of talc filler masterbatch offers several advantages in various industries:

1.2.1. Improved mechanical properties

One of the most significant advantages of using talc filler masterbatch is its ability to enhance the mechanical properties of plastic materials. The addition of talc, with its unique structure and properties, can increase stiffness and tensile strength, making the final product more robust and durable. This improvement is particularly valuable in applications where structural integrity is critical, such as automotive components and construction materials.

1.2.2. Enhanced thermal stability

Talc is known for its high thermal stability, and when incorporated into plastic matrices, it can significantly improve the heat resistance of the material. This is crucial for applications that involve exposure to high temperatures, such as injection molding or extrusion processes. Talc-filled masterbatch helps plastic products maintain their shape and structural integrity even under elevated temperature conditions.

1.2.3. Cost efficiency

Talc filler masterbatch provides a cost-effective solution for plastics manufacturers. By reducing the amount of pure polymer needed to achieve the desired performance characteristics, it helps lower production costs. Moreover, it enhances the processing efficiency, leading to shorter cycle times and increased productivity, ultimately contributing to cost savings.

1.2.4. Weight reduction

The addition of talc filler masterbatch allows manufacturers to reduce the weight of plastic products without compromising their mechanical strength. This is especially advantageous in industries where lightweight materials are desirable, such as the aerospace and automotive sectors. Lower weight not only improves fuel efficiency but also reduces transportation and handling costs.

1.2.5. Improved surface finish

Talc-filled masterbatch can contribute to a smoother and more aesthetically pleasing surface finish for plastic products. This is valuable in consumer goods and packaging applications where appearance and texture play a crucial role in consumer appeal.

In summary, talc filler masterbatch is a versatile and cost-effective solution for enhancing the properties of plastic products. Its use can lead to stronger, more durable, and aesthetically pleasing end-products while simultaneously contributing to cost savings and environmental sustainability. These benefits make it a sought-after choice in many industries, and the exporters of this material play a significant role in meeting the global demand for talc filler masterbatch.

2. Top 5 famous talc filler masterbatch exporters

2.1. PolyFill

PolyFill is a renowned exporter of talc filler masterbatch based in Hai Phong, Vietnam. We are known for its exceptional product quality and commitment to innovation. We offer a wide array of talc-filled masterbatches, each tailored to specific industrial needs. PolyFill‘s masterbatches are characterized by their high talc content, which enhances the stiffness and impact resistance of plastic materials. This makes our products ideal for applications in the automotive and construction industries where structural integrity is paramount. Our products are also favored for their excellent dispersion, ensuring uniformity in the final plastic product.

2.2. EuroPlas

EuroPlas, a prominent company in Vietnam, is a reliable source for talc filler masterbatches. They have a strong presence in the market due to their extensive experience and commitment to customer satisfaction. EuroPlas masterbatches are formulated to meet the stringent demands of industries such as automotive, packaging, and construction. These masterbatches excel in enhancing the thermal stability of plastic materials, ensuring they maintain their properties even under high-temperature conditions. EuroPlas is also recognized for its ability to offer customizable solutions, tailoring masterbatches to meet specific client requirements.

2.3. Sunrise Colours

Sunrise Colours has earned a solid reputation as an exporter of high-quality talc filler masterbatches. Their range of products is known for its consistency and compliance with international standards. Sunrise Colours masterbatches are designed not only to improve the mechanical properties of plastics but also to meet environmental and regulatory standards. These masterbatches find applications in diverse industries, and their excellent dispersion characteristics ensure a smoother surface finish, making them suitable for consumer goods and packaging applications.

2.4. Dai A Industry

Dai A Industry, based in Vietnam, is a respected exporter of talc filler masterbatches. With a focus on research and development, they have created innovative masterbatches that enhance the properties of plastics, especially in agriculture and consumer goods sectors. Their masterbatches are recognized for their ability to reduce the weight of plastic products without compromising strength, making them valuable in industries where lightweight materials are essential. Moreover, Dai A Industry is committed to cost-efficiency and productivity, contributing to the overall competitiveness of their clients.

2.5. Tan Hung Co

Tan Hung Co is a well-established name in the field of talc filler masterbatch exports. Their dedication to quality and customer satisfaction has made them a reliable source for masterbatches that cater to diverse industry requirements. The masterbatches offered by Tan Hung Co are tailored to specific applications, ensuring they meet the unique needs of clients. Their products are characterized by their ability to improve the mechanical properties of plastics, resulting in durable and high-performance materials. Tan Hung Co’s masterbatches have a wide range of applications across industries.

3. Conclusion

In the dynamic world of plastic manufacturing, the right choice of filler masterbatch exporter can make a significant impact on your products’ performance, cost-efficiency, and competitiveness. As we’ve explored the top 5 famous talc filler masterbatch exporters, it’s clear that the industry is filled with leaders dedicated to providing high-quality solutions. However, one name stands out as a pioneer in the field, pushing the boundaries of what plastics can achieve: PolyFill. PolyFill is more than just a manufacturer; we are enablers of success. With a steadfast commitment to excellence and innovation, PolyFill has revolutionized plastic manufacturing by offering a diverse range of filler masterbatch solutions, each bearing the hallmark of quality.

Our product range is designed to cater to the unique needs of various industries:

- PP Filler Masterbatch: PolyFill’s PP filler masterbatch combines premium PP resin, high-quality calcium carbonate (CaCO3), and carefully selected additives. This innovative product sets new benchmarks for strength, durability, and cost-efficiency, making it an ideal choice for applications demanding resilience and competitiveness.

- PE Filler Masterbatch: Formulated with top-tier PE resin, high-grade CaCO3, and thoughtfully incorporated additives, PolyFill’s PE filler masterbatch offers a winning combination of strength, flexibility, and affordability. It’s engineered to elevate product performance while maintaining cost-effectiveness.

- Transparent Filler Masterbatch: Transparency meets strength in PolyFill’s transparent filler masterbatch. By blending inorganic transparent powders like BaSO4 or Na2SO4 with PP or PE resin and synergistic additives, this solution is ideal for applications where both aesthetics and functionality are paramount.

- HD Filler Masterbatch: Harness the power of PolyFill’s high-density (HD) filler masterbatch, featuring a polyolefin carrier infused with CaCO3 and specialized additives. This product is engineered to bolster density, mechanical properties, and overall product value.

- HIPS Filler Masterbatch: Experience the difference with PolyFill’s HIPS filler masterbatch, which incorporates a substantial portion of pure CaCO3, thoughtfully selected additives, and plastic resin. It’s a game-changer in enhancing both the visual appeal and performance of your products.

PolyFill understands that different industries and applications demand specific attributes from plastics. Our filler masterbatch solutions are designed to be enablers of success, providing innovation, efficiency, and enhanced sustainability. When you partner with PolyFill, you gain access to a world of transformative plastic manufacturing.

Elevate your plastic manufacturing processes with PolyFill’s filler masterbatch solutions. Whether you’re looking to optimize costs, enhance performance, or reduce your environmental footprint, PolyFill’s range of products is tailored to cater to your unique requirements. Reach out to us today and embark on a journey of transformative plastic manufacturing.