Every day you can use plastic cups, dining tables, utensils, bottles, jars, baskets, etc. From many years ago, these items are all produced by injection molding of polymer. In the following article, we not only discuss about the process of making plastic chairs. In additions, we also reveal how manufacturers use filler masterbatch to achieve optimal profit today.

A basic injection molding process (without masterbatch)

In principle, injection molding is simple. So, producers will melt plastic, inject it into a mold, let it cool and then out pop products. However, the injection molding is an intricate and complex process.

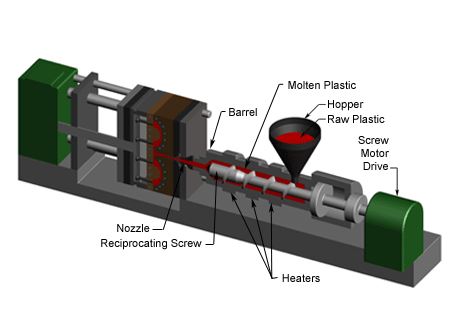

An injection molding machine has 3 main parts: injection unit, mold and the clamp. First, plastic pallets in the hopper feed into the barrel of the injection unit. Inside the barrel, a screw transports the pellets forward. During this activity, heater bands wrapped around the barrel and warm up the plastic pellets. As the pellets moved forward by the screw, they gradually melt and are entirely molten by the time. Next, they reached the front of the barrel.

Once enough melted plastic is in front of the screw, it ramps forward and let the plunger of a syringe. In a matter of seconds, the screw injects the molten plastic into the empty part of the mold. People call it as cavity image. The plastic solidifies in under a minute. The mold opens and the part is ejected. Then, the mold closes and the process repeats from beginning.

All injection molded objects start with these plastic pellets which are a few millimeter in diameter. Manufacturers can mix them with small amounts of pigment known as colorant or with up 15% recycled materials, then fed into the injection molding machine.

Innovations in applying filler masterbatch to injection molding process

In order to gain more benefits and keep good product quality, manufacturers have found more ways to improve their process. Using filler masterbatch is a good way.

In fact, they will select one among popular types of plastics to make chairs, such as PP plastic. For example, from the beginning of the production, instead of using 100% PP plastic, they reduce amount of PP. Then, they mix the rest with PP filler masterbatch and other additives. In case, if they want their chair to become more hard, they can add glass fiber. Finally, Outputs are still guaranteed about quality, color and functions but cost to produce them is less. Because filler masterbatch is cheaper than PP, so manufacturers can save their money after all.

Besides, to make chairs colorful, manufacturers can use color masterbatch. Since it brings bright color and blend it well more than pigment. For instance, with white masterbatch from Polyfill, you can produce white chairs and do not need to worry if color dispersion is good or not. This performance is similar with other colors like black masterbatch, blue/yellow/green/brown masterbatch…

At present, there are some manufacturers want to reduce time to find each material, supervise workers at the factory, electric cost…Instead of using filler masterbatch, they can order compound – which is followed to their formulas from suppliers, so as to focus on products and sales.