Recycled plastics have been used in cars for over a decade. However, you may not see them because they are located below the interior or inside the vehicle structure for example. In terms of total vehicle weight, they do not occupy much. Plastic waste can be a threat to many people, but for manufacturers, this is a source of recycling their raw materials. Along with the pressure of media mass and the change in people’s awareness of the environment, their ideas are further confirmed. However, they not only using recycled plastic, but also combine them with CaCO3 masterbatch on resin (PP, ABS, PVC, PS…), additives and compound. Especially when the quality of recycled materials is increasingly improved, manufacturers started to utilize them more in some places easier to see on vehicles. Some electric vehicle manufacturers have led this innovation.

Manufacturers leading to use recycled plastics in electric cars

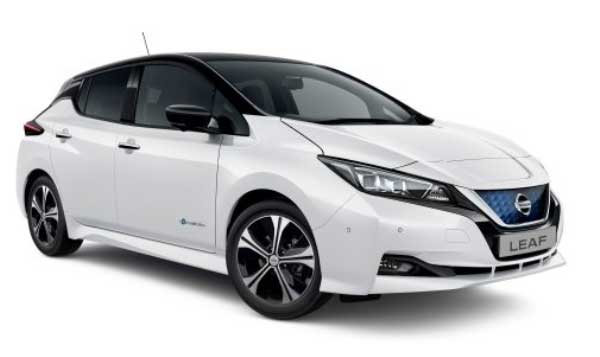

Nissan Leaf

Nissan Leaf seeks a solution to handle all waste, from simplified design to disposal. About Nissan Leaf car weight, almost 25 percent is made from recycled plastics. They used PET soda bottles which are used and recycled to make seats. In another attempt to finish the center console and soundproof padding, they use parts from old electrical equipment and recycled fabrics. In addition, Nissan Leaf also uses recycled plastic to produce car doors.

BMW I3

Under the pressure of the environmental protection campaigns, users not only pay attention to recycled plastic on the car parts. Therefore, BMW has changed the way they complete car interior in a green way. According to traditional methods, formaldehyde is often used to make building materials or many household products. People also used it as an option in tanning leather seats. However, long-term exposure to formaldehyde is harmful to the user’s health and the environment. Hence, BMW used olive leaves for their leather seats. In addition, they use renewable natural fibers panels on the doors as well.

Toyota Prius

After more than 10 years since the development from sweet potatoes, sugarcane, Toyota is confident to produce auto parts from bio plastic . Their typical products are the scuff plates, deck trim and seat cushions. For examples, with interior trims or scuff plates, they can mix PLA ( polylactic acid or polylactide) with polypropylene (PP).

CaCO3 masterbatch combines with recycled plastic – why it should be?

One of the problems of metal car manufacturing is that metals are often not pure enough to be recycled and make new automotive parts at the end of its life cycle. In addition, vehicle weight is one of the important factors that manufacturers are interested in. The lighter your car is, the less energy it consumes. Hence, with the advantage of being a leader in producing electric cars in future, they want to find lighter materials but still meet the production techniques of cars. In this case, recycled plastic is a good option for them. Not only is it lighter than metal but it also reduces the production of C02. Some types of recycled plastic used for electric cars are PP, PE, PET, PS…

Although it has many benefits in electric cars, recycled plastic also has certain limitations.

Because it was used before, recycled plastics are inexpensive any more. However, their properties will tend to be low and unstable if manufacturers do not handle it well. Therefore, in the production process, they can use CaCO3 masterbatch. Because the types of calcium carbonate masterbatch (caco3 masterbatch) based on resins suitable for cars, they help them reduce costs as well as increase resistance to shrinkage.

From Polyfill, manufacturers can use PP calcium carbonate masterbatch in automotive bumpers, chemical tanks, insulation cables, gas cans or carpet fibers. When they want good chemical and electrical resistance, they can use HIPS calcium carbonate masterbatch. Some of its applications on electric vehicles that we easily meet are equipment housings or car fittings and buttons. Another type that is quite popular among manufacturers is PE calcium carbonate masterbatch. PE has high impact resistance and flexibility. It can be used in many methods of treating thermoplastic such as injection molding and is particularly useful when it comes to low moisture resistance. That’s why manufacturers either use PE CaCO3 masterbatch into car bodies or electrical insulating parts to reduce the amount of PE needed and still achieve the performance and quality.

1 Comment

Hi there, this weekend is pleasant in support of me, since this moment i am reading this impressive educational article here at my house. Kayla Tamas Kiyohara