In 2016, there is a total of 485 billion PET bottles were manufactured, nearly 1 million bottles purchased per day and it is estimated to reach 583 billion in production unit in 2021. PET bottle manufacturer has become an industry of itself, gaining a mass of billion dollar in profit every years. Plastic bottle production is also a challenging process that involves advanced machine aid, engineering skill and a science behind its mechanism.

Select the optimal type of plastic

Almost all plastic drink bottles used today are made from polyethylene terephthalate (PET), since PET IS known for its duration and lightweight. With the exception of Coca-cola’s Bio-based PET, the majority of PET plastic is extracted from crude oil, then polymerized to form long chains of molecular.

In its pre-manufactured form, PET often takes the shape of granules. The granule shape is purposefully designed to match the ease of transportation and molding procedure.

Bottle caps are usually made from another material. The three common types are HDPE (high density polyethylene), LDPE (low density polyethylene), PP (polypropylene). There is a purpose behind the use of each design, as the bottle cap can select the suitable plastic to either enhance its hardness, softness or bpa-free components.

Bottle caps are made from a distinct type of plastic from the material of the bottle.

At the very first stage of the manufacturing process, several tests are put through to check the resistance of the plastic against carbon dioxide, especially for soda-can bottles, transparency, color, thickness, etc. All tests are conducted with care as once the process goes into routine, the chance of delivering failed product is significantly high.

The manufacturing process takes place in three primary stages: injection molding, stretch blow molding and cooling.

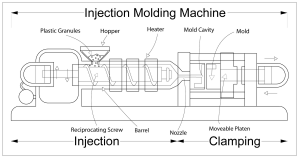

Injection molding is often considered as the primary stage of stretch blow molding and a part of its process. In this stage, the PET granules are transferred into a hopper and delivered through a heater tube in accelerated temperature. As the granules melt under the extreme thermal environment, the liquid is forced into a mold with the shape of a long tube. The process of mold capvity and release is referred to as the clamping process.

Mechanism of a injection molding machine

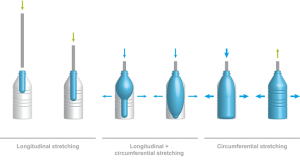

The next step replaces the tube shape by a bottle-shaped mold. A mandrel, a type of steel rod, is inserted into tube and pushes in extreme compressed air. Under heat and pressure, the plastic tube is blown and stretch in to the mold, forming the shape of a bottle.

Mechanism of stretch blow molding

Stretching strictly follows three steps. A longitudinal stretching extend the length of tube. Once the length reached half of the bottle shape, a circumferential streching is added, in which the width of the tube is expanded towards the surface of the bottle mold. After achieving the optimal length, circumferential streching continues to process, ensuring the layer of plastic clinging into the mold.

Cooling Process

The newly-made bottle must be cooled within the mold so that its structure is set. The mold can be cooled via direct temperature reduction or coursing water through the surrounding pipes. During this process, PET is often mixed with a release agent to ensure the parts will be effortlessly released from the molding machine.

The result would be the plastic bottles commonly seen today

We are Vietnam’s leading provider of filler masterbatch and masterbatch. With the enormous CaCO3 resource in Vietnam, we offer the most cost-effective PE, PP, HD and HIPS filler masterbatch at the best quality. Our factory is located near the seaport of the Hai Phong Industrial Province, an ideal location to deliver our pacels oversea.

Visit our homepage for more details:

✔ https://polyfill.com.vn/

Or contact us at:

✔ info@polyfill.com.vn