Raffia is one of the main sectors of the plastic industry with tremendous vital outputs such as woven sacks, jumbo bags, shopping bags,… As the use of calcium carbonate fillers for raffia is getting more and more popular, it’s vital to figure out the most appropriate ones in order to achieve the highest production efficiency. Discover this article below to get yourself the answer!

First of all, let’s take a brief look at the raffia industry to get to know its common end-products and manufacturing components.

1. What is raffia technology and its outputs?

Going Google with the word “raffia”, most results we have are about a type of palm. Don’t let yourself be confused as the “raffia” we are looking for is a type of polymer processing technology. In which, flat tape yarns made of specific polymer combinations are formed by a weaving process.

In fact, the idea to produce flat tape yarns was first initiated in the early 1930s by Jacque and his co-workers at the I.G. Farbenindustrie AG. However, it proliferated only when high-density polyethylene (HDPE) and polypropylene (PP) came into commercial reality. Thanks to their great stretch ability, these polymers quickly become indispensable parts in producing raffia products till now. These largely affect the choice of calcium carbonate fillers for raffia, which will be discussed later.

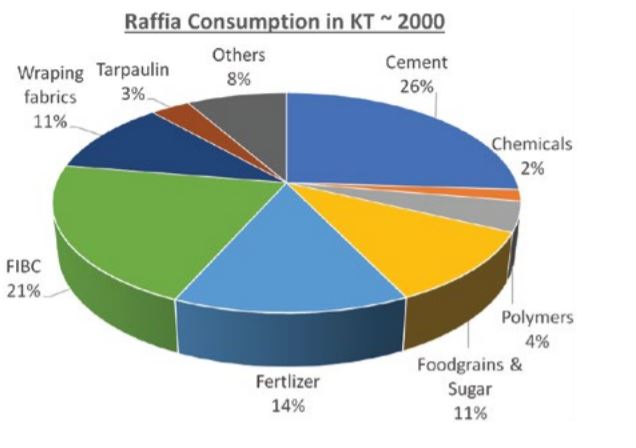

With the rising demand in the end-use market, the outputs of raffia industry have constantly developed and encompassed a wide variety of applications, ranging from traditional woven sacks to flexible intermediate bulk containers (FIBCs) and technical fabrics (such as geotextiles). Generally, it is classified into the following categories:

- Woven sacks for packaging of cement, fertilizer, animal feeds, grains, sugar, polymers, chemicals

- Flexible Intermediate bulk containers (FIBCs) or jumbo bags

- Tarpaulins

- Wrapping fabrics

- Other applications

In which, the largest sector is represented by woven sacks, followed by flexible Intermediate bulk containers (FIBCs), agricultural packaging, wrapping fabrics, tarpaulins, geotextiles, geomembranes, webbings, lifting slings, ropes and other applications. Globally, the production of woven fabrics is around 16.1 mMTA and it has reached 4.8% CAGR over the last 5 years (Lohia Corp Journal, 2019).

2. Which are recommended calcium carbonate fillers for raffia?

Calcium carbonate filler has now become an effective material solution for plastic enterprises. Its applications have encompassed from injection moulding, blown films, blow moulding, extrusion to raffia and make an impression by its various benefits.

Related: What is filler masterbatch? How is it applied in the plastic industry?

In raffia, the use of filler masterbatch is one of the key factors to the success of the end-products. As mentioned above, woven fabrics are mainly made of HDPE (high-density polyethylene) or PP (polypropylene). Hence, to attain the compatibility between fillers and plastic resins, the most recommended calcium carbonate fillers for raffia are HDPE/PP calcium carbonate fillers. This correspondence not only ensures that polymer combination is well-mixed but also provides end-products’ surface with a great dispersion.

Thanks to the composition of PP/HDPE resins, CaCO3 powder and specific additives, filler masterbatches can help plastic enterprises significantly save the production cost. Besides, they also enhance end-products’ mechanical characteristics (bend resistance, impact strength and printability). The use of calcium carbonate fillers for raffia also make woven fabric be more well-in-shape in the thermal processing phase as it increases the stability during the manufacturing process. Furthermore, since CaCO3 is a good thermal conductive, it considerably shortens the time required for each product cycle, thus boosting production efficiency.

Another plus point of this material is how it actively contributes to environmental protection. With the presence of filler masterbatch, plastic enterprises can cut down on the amount of fossil resins consumed, which also means reducing the carbon footprint released into nature. The lower proportion of fossil components also benefits the end-user as the excessive exposure to fossil materials in bulk more or less raises health concerns.

Related: 4 reasons to apply calcium carbonate filler in polypropylene

3. Common applications of HDPE/PP calcium carbonate filler in raffia

Thanks to its great advantages, HDPE/PP calcium carbonate fillers are widely used in various raffia applications:

Woven sacks

The most popular application of calcium carbonate filler in raffia is definitely woven sacks. An important use of woven sacks is for cement packaging. Due to PP filler’s higher stiness, adaptability for hot content and better dimensional stability at higher temperatures, it is specifically preferred in cement packaging. For fertilizer packaging, laminated HDPE bags are predominantly used owing to its better outdoor stability than that of polypropylene. Another common sector of woven sack consumption is agricultural product packaging, ranging from onions, potatoes, garlic, carrot, ginger to pineapples, oranges,… and other types of fruits and vegetables. Leno bags can be seen as a typical representative of this sector thanks to its low weights and cost-effective nature. Also, it allows the air to pass through the sack to keep the product fresh.

Related: Advantages of using PE filler masterbatch in producing films

Jumbo bags/FIBCs

Jumbo bags and FIBCs are the second largest sector of the raffia end-use market. They are one of the most cost effective and ideal types of packaging for shipping and storing dry bulk goods, especially powdered and granular materials like chemicals, petrochemicals, minerals, building materials, fertilizers, grains. The application of calcium carbonate filler in jumbo bags reinforces certain mechanical properties of end-products such as impact strength, printability,…

Related: How to make plastic bags with masterbatch?

Geosynthetics

Geosynthetics segment, which includes geotextiles, geomembranes and other geo-engineering products, is a relatively new entrant in raffia industry. For this sector, the use of PP woven dominates raw materials consumption, paving the way for the proliferation of PP calcium carbonate filler for raffia, which not only remarkably saves production cost for plastic enterprises, but also contributes to the environmental protection.

In short, thanks to its outstanding benefits, HDPE/PP calcium carbonate filler is amongst the most appropriate types of fillers for raffia. However, to achieve the best result, plastic enterprises need to consider other criteria such as denier, speed of extruder, tape width, tenacity, elongation, draw ratio,… as the choice of calcium carbonate fillers for raffia largely depend on them.

Related: 4 most common PP calcium carbonate filler’s applications in the plastic industry

4. PolyFill calcium carbonate fillers for raffia

As one of the leading manufacturers in producing calcium carbonate fillers, PolyFill takes pride in providing customers with the highest-quality materials. Specifically, our fillers are tailor made based on your end-products’ requirements to ensure that they disperse well on end-products’ surface and are able to exactly meet end-users’ demands. Furthermore, the use of filler masterbatch also helps save production cost, while enhancing various mechanical properties such as impact strength, tear resistance, and printability,…

For further information and consultation, don’t hesitate to contact us HERE!